Keep Up to Date with MDG

MDG News and Updates

Your Custom Microbial Fermentation Roadmap

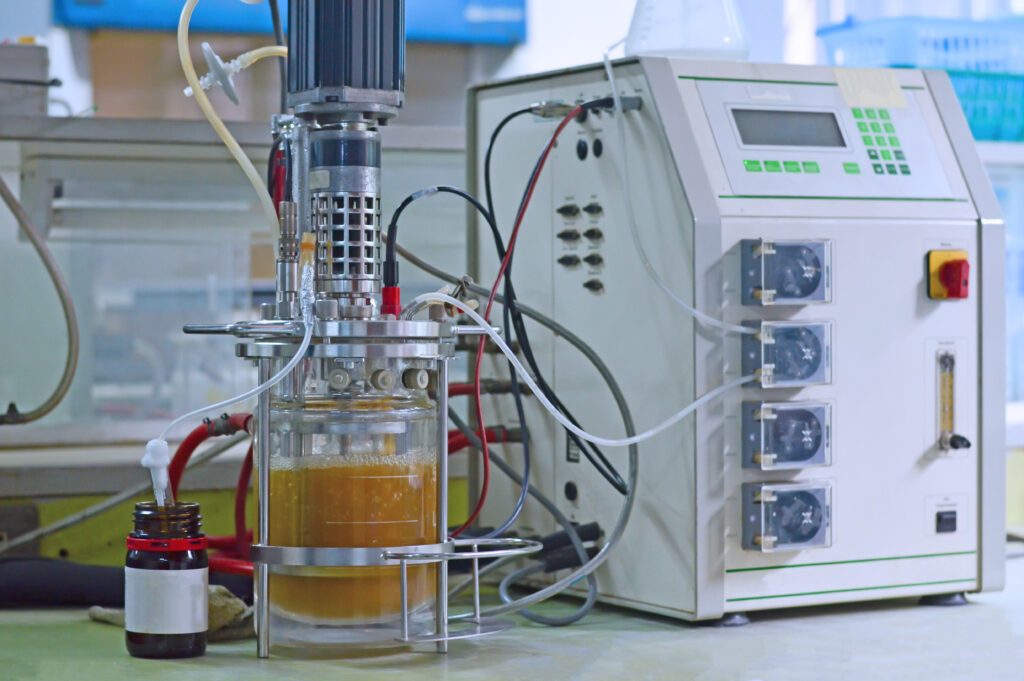

When you partner with MDG for your custom fermentation needs, you can be confident that our microbiologists and production experts are committed to delivering a final culture that fits your specifications. We follow our Trusted Process closely, fostering success for our customers. But what does that process look like? Read on to discover what our custom microbial fermentation process entails, from pilot scale to commercialization. Part One: Rapid Scale-Up When you begin the custom fermentation process with MDG, your Bacillus strain will go through a process development program. This stage typically takes about twelve weeks to complete. The process development steps are as follows: MDG receives your strain in our in-house labs. Our microbiologists streak your strain to ensure purity. An initial growth screen begins, during which our specialists test your Bacillus strain’s growth ability on a multitude of different media. Growth media is narrowed down to a few top choices, and additional testing is performed to find the optimal media for your strain. Once we’ve found the right growth media, we will grow your strain on a pilot scale, harvest and dry the culture, and send it to you for evaluation. After you give your approval on the final […]

Bacillus-based Cleaning with Jennifer Cray

This is MDG The: Podcast with experts in the field of microbiology, teaching us about the world we live in and how Bacillus is shaping it. We put this summary together taken from the transcript, for more details and to hear straight from Jenny, head to the podcast! Listen and Subscribe: on Podcast Page, Apple Podcast, Spotify The Episode What is Bacillus? A naturally occurring bacteria, Bacillus, are put to work in many industries for their diverse capabilities such as the human and animal, plant, wastewater, and industrial and institutional and consumer (IIC) markets. How are Bacillus able to use their unique properties to clean? Bacillus bacteria are effective in IIC applications because they can digest substances like carbohydrates, fiber, and fats, oil, and grease (FOG). They release enzymes and some produce beneficial compounds like biosurfactants that help to break down stains. What types of applications do you recommend for microbial cleaners? Microbial cleaners are effective cleaning and odor-reduction solutions. They are able to clean and reduce odors in various applications by reaching hard-to-clean places like carpets, grout, or porous surfaces and digest the soils accumulated there. This makes them a valuable and effective cleaning solution. How do microbial cleaners […]

The Key Drivers Behind MDG’s Current Expansion

I was recently asked the WHY behind our current expansion. When I started to break it down, there were 4 key drivers that went into the new MDG facility design: Capacity expansion Reliability via redundancy Production of 50+ strains The expanding Bacillus marketCapacity expansion. This is the no-brainer for expanding. MDG was reaching 75% of our capacity, so we either had to expand or recognize there would be a future cap on what we could offer to our customers. With internal goals already in place to increase the reach of our offerings by 2020, we realized expanding was our best option. Reliability via redundancy. When you visit MDG you will see a very deliberate and intentional attempt at redundancy. To be reliable day in and day out, redundancy in equipment is vital. Let’s face it, equipment breaks down from time to time, but we don’t want our customers to have to suffer. At MDG, we have focused on setting up a model where we have multiple fermentors, centrifuges, freeze dryers, boilers, air compressors, chillers and sterilizers to back up our promise to deliver. We have a backup generator in place to guard against brown outs in electrical utility supply. We […]

The Importance of Strain Purity Testing in Custom Fermentation

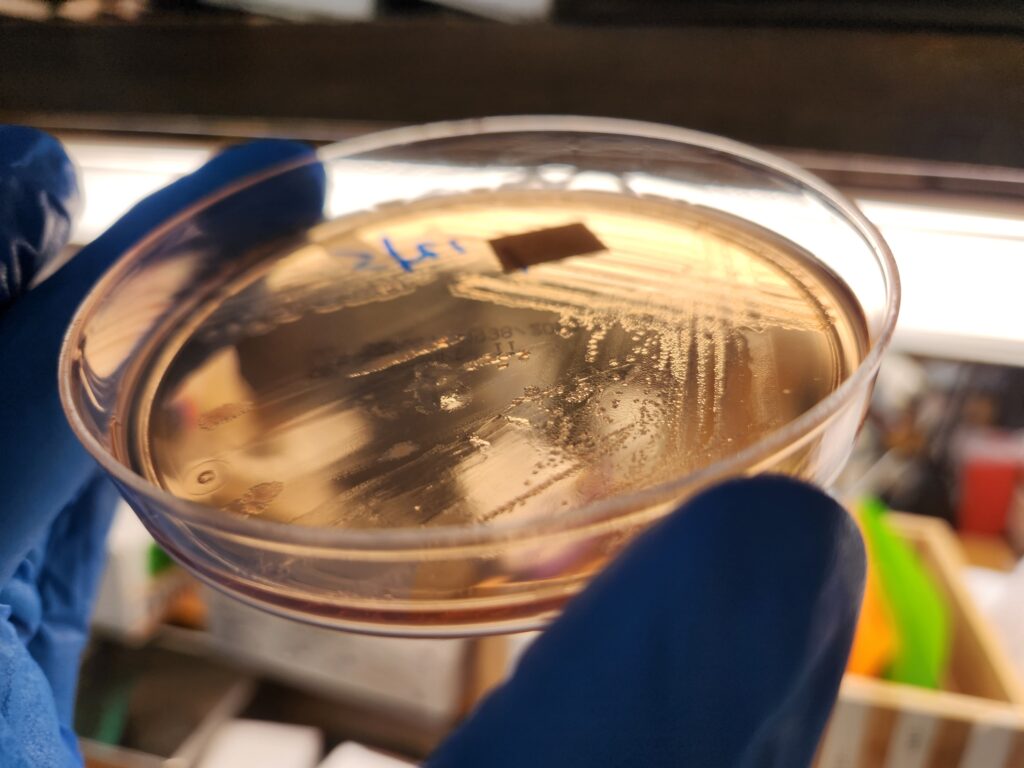

At MDG, we are Bacillus experts with over 20 years of experience growing pure cultures for our customers. We are continually honing our methods to find the most effective, efficient way to create quality microbial ingredients, and one contributing factor is purity testing. From performing testing through strain typing methods to producing and selling only single-strain tanks, let’s explore the process of purity testing to find out why creating effective microbial products happens one strain at a time. What is strain purity testing, and how is it done? Strain purity testing is the process of checking a growing Bacillus culture to ensure it is a match for the target strain. Testing can also confirm that there are no non-target organisms present in the culture. Purity testing can be done in a multitude of ways. We have a variety of genomic methods at our disposal that allow for thorough, efficient testing of each Bacillus culture. Testing is conducted at several steps of the process, including: Seed bank Inoculation flask Fermentation tank Dried culture (finished product) Monitoring the purity of the culture at multiple points allows us to catch and correct any potential errors as soon as possible and keep the process […]

MDG’s Solutions to Portable Toilet Odors: A Guide for Distributors

As summer begins, outdoor events, construction projects, and gatherings become much more frequent, and portable toilets usually found at these locations can present a significant odor challenge. Managing those odors is essential for maintaining both public and environmental health. At MDG, we have extensive experience in microbial technologies, and our advanced biological solutions provide an innovative approach to tackling these odors effectively. Odors Have an Impact Odor control affects not only user comfort but also the overall acceptance and viability of portable toilets at public and commercial venues. When not properly addressed, the odors that portable toilets cause can cast the event—and potentially the portable sanitation suppliers—in a negative light. Effective odor management, on the other hand, can enhance customer satisfaction and bolster the reputation of distributors and event organizers alike. The Impact of Our Products Microbial solutions are a great way to combat odors, particularly in the application of portable sanitation. Unlike traditional chemical options, our biologically based treatments utilize Bacillus to digest waste materials, effectively reducing odors. A solution like this not only minimizes unpleasant smells but also contributes to a healthier environment by reducing the reliance on harsh chemical agents. MDG’s microbial products are also created with […]

A Guide to Wastewater Success: People, Products, and Programs

Working in the wastewater treatment industry comes with its challenges. Your customers may face problems like sludge buildup, odors, hydrogen sulfide (H2S) production, and fats, oils, and grease (FOG) accumulation. As their supplier, you need a solution you can count on to help them succeed. That’s where we come in with our innovative, research-based, and hands-on platform: Biotifx®. Our Biotifx® platform includes access to our wastewater treatment product line, expert-led training to drive application success in the field, and continual support from our team members throughout the sales process. We break these benefits into three main categories: People, Products, and Programs. Read on to learn more about each of these three pillars and how MDG’s Biotifx® platform can help you bring successful Bacillus-based solutions to your customers working in wastewater treatment. People When you partner with MDG, you can trust that we are dedicated to helping you achieve your goals in the marketplace. From training and field support to assistance with administrative tasks like product line development and private labeling, we walk with you on your wastewater bioaugmentation journey to show you just how successful you can be. We know how important it is to talk to real people to […]

2023 EXPANSION: CONTINUED GROWTH

In 2021, our growth journey took a significant leap as we secured an 80,000 ft2 facility in Oak Creek, WI. This expansive space now accommodates our production, blending, packaging, warehouse, three laboratories, and supplementary office areas. In addition, an external structure was built to house a 34-ft spray dryer and pilot spray dryer. The completion of the MDG Oak Creek facility in Fall 2022 marked a major milestone. Since then, we’ve settled into our new Oak Creek home while amplifying operations at our Franklin facility. Our Franklin facility, now with four fermentors and a 35,000L total capacity, is a key player in our growth. As we continue to develop, our custom fermentation capacity is growing in current and future markets. Our driving force is applying Real Science, to a Trusted Process, yielding Proven Success. Contact Us to learn more about our evolving Custom Fermentation capabilities and how to become part of our ongoing journey!

Under The Microscope – Sierra Garcia

At MDG, we succeed by creating an environment to attract, develop, and retain the best and the brightest people who embrace our values. Learn all about Sierra Garcia, our Engagement Coordinator. What is your role at Microbial Discovery Group (MDG) and when did you join the team? I am the Engagement Coordinator at MDG, and I joined back in April 2022 as Receptionist but quickly found a passion for our engagement and onboarding needs at MDG. What initially drew you to MDG? I was a referral of one of our Bio-Manufacturing Operators and he would always share stories about the CEO, Mike King, the culture, and the work. After interviewing and finding out the mission, I knew this was where I wanted to spend my career. Helping to Feed, Clean, Save the World! What about the work you do at MDG that drives and fulfills you? I can say the biggest thing that drives me is the people I work with. In hectic times, my MDG team can brighten my day. When I’ve done something good, my MDG team notices and cheers me on. When I see one of my co-workers having a bad day, I encourage […]

Unlocking Solutions: Managing FOG in Wastewater with Bioaugmentation

Unlocking the mysteries of Fats, Oils, and Grease (FOG) mitigation and management within wastewater is crucial for maintaining a sustainable and efficient system. In our upcoming webinar, we delve into the reasons why FOG poses a significant challenge, exploring its impact on sewers, pipes, and interceptors, lagoons, and activated sludge systems. Josiah Menako, MDG’s Technical Support Lead, will uncover the disruptive effects FOG has on wastewater systems, from collection systems to treatment plants, presenting a comprehensive view of the added complexities. Menako will discuss the value of improving and controlling FOG, shedding light on opportunities for decision-makers and providing real-world cases for reference. The webinar will not only address the problems but also present viable solutions, covering point source mitigation, mechanical removal, chemical additions (including enzymes, degreasers, and caustic substances), and the fascinating realm of biological digestion involving genetics, enzymes, and bacteria. Don’t miss out on this enlightening session, complete with insightful case studies that showcase successful strategies for combating FOG in wastewater systems. Unlocking Solutions: Managing FOG in Wastewater with Bioaugmentation is taking place on March 14, 1 PM CST. Click here to register.

Battling Restroom Odors: Debunking Ice in Urinals

Ever since the invention of the urinal back in 1886, facilities have been battling the unwanted odors that come with them. To combat the odors, businesses have tried many different treatments… some more beneficial than others. One of the most used techniques for businesses is to fill the urinal with ice. However, this may add to the odor in restrooms. In this post we discuss why utilizing the power of Bacillus over loading ice into urinals will be your best bet to reducing those odors. The Unintended Consequence of Using Ice in Urinals The rationale behind the ice method is logical but unknowingly, not directed at the true cause of the odors. The belief is that the odor from restrooms is due, in part, to lack of flushing, so businesses will load in ice. The ice slowly melts, providing a constant flow of water through the urinal. While having a consistent water flow can help keep drains running smoothly, the unintended consequence is that ice can often lead to splashing which only intensifies odors. When urine splashes onto porous surfaces, such as tile and grout, it leads to the accumulation of urine and urea. This results in strong ammonia odors. […]