The changing of the seasons can have a pronounced effect on wastewater systems, particularly when the weather gets cold. Lower temperatures correspond to a decrease in microbial activity, which slows the wastewater treatment process. If you’re looking for a solution for your wastewater customers, we offer a Bacillus-based product specifically designed to perform well in colder water temperatures: Biotifx® FRZ.

How does Biotifx® FRZ work?

The Bacillus strains in Biotifx® FRZ are scientifically selected for their ability to maintain their biological activity in colder water, specifically temperatures at or below 59°F/15°C. This means that treatment doesn’t slow down as much during winter, keeping wastewater facilities functioning more efficiently and avoiding system upsets caused by seasonal changes.

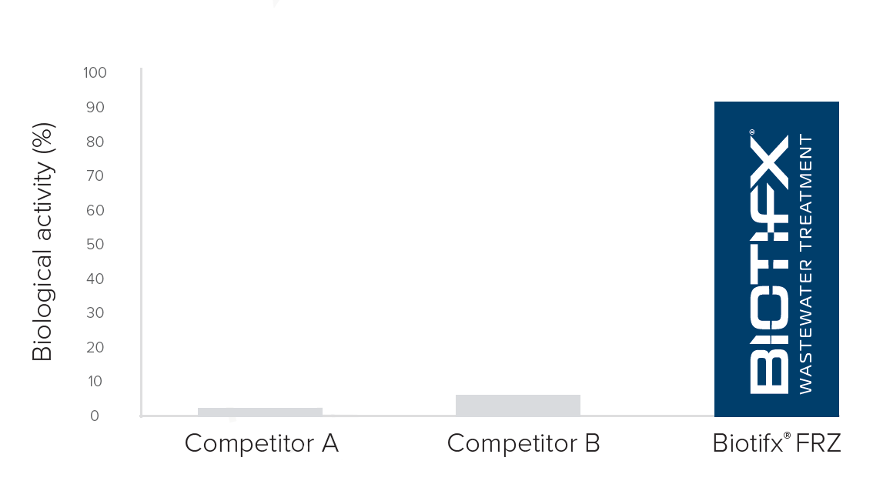

In our in-house labs, we put our Bacillus solution to the test against competing cold-weather biological products. Overall, Biotifx® FRZ performance stayed consistently high across both colder and warmer temperatures.

Biotifx® FRZ Bioaugmentation vs. the Alternatives

Biological Activity Comparison

As shown in Figure 1, FRZ maintained 92% of its biological activity during a drop in temperature from 77°F/25°C to 39°F/4°C. In comparison, the two competitor products we tested maintained only 1% and 5% of their biological activity throughout the same decrease in temperature.

Figure 1: Comparing biological activity at 39°F/4°C to that same activity at 77°F/25°C.

Dairy Wastewater Testing

We also tested the effectiveness of FRZ in a dairy facility wastewater sample at 39°F/4°C and 68°F/20°C. When the wastewater was untreated, the colder temperature severely limited microbial activity and reduction of biological oxygen demand (BOD). Biotifx® FRZ improved BOD reduction during warm weather and maintained efficacy while at 39°F/4°C (Figure 2). This allows for effective and consistent wastewater treatment throughout the winter and into spring.

Figure 2: Untreated vs Biotifx® FRZ BOD reduction in dairy wastewater.

Pulp and Paper Wastewater Testing

Lastly, we tested the application of Biotifx® FRZ in an industrial pulp and paper facility setting. Results were similar to our dairy wastewater test, but even more pronounced. FRZ greatly improved BOD reduction both during warm weather and cold weather compared to the untreated sample (Figure 3).

Figure 3: Untreated vs Biotifx® FRZ BOD reduction in industrial pulp and paper wastewater.

How should I direct my customers to use Biotifx® FRZ?

A few months before temperatures start to drop, encourage your customers to switch their bioaugmentation treatment to FRZ. This way, they’ll be ahead of the curve when winter comes and won’t experience such a drastic decrease in microbial activity.

Partner with MDG for Cold-Weather Bioaugmentation

Interested in becoming an MDG distributor so you can start selling FRZ to your customers? Contact us today for more information about how to partner with us!

MDG is the Bacillus solution that helps you scale and streamline without sacrificing product effectiveness.