Earlier in this article series, we touched on how bioaugmentation treatments for wastewater have been around for 50+ years to help resolve toxic upsets. We also explored how Bacillus, a certain genus of bacteria that can be used in microbial treatments, are resilient to oxidizers.

Today, we’ll examine how Bacillus are resistant to another powerful but non-oxidizing anti-microbial: Quats.

What are Quats?

Quaternary ammonium compounds (QAC, also referred to as “Quats”) are potent disinfectant ingredients found in both household and industrial cleaners. Some common examples are benzalkonium chlorides (BAC, BZK, BKC), alkyl dimethyl benzyl ammonium chlorides (ADBAC) and several other compounds identified by the words ‘ammonium chloride’ at the end of their names.

How Quats Work

Quats kill bacteria by puncturing or disorganizing the cell membrane, leading to interior component leakage and ultimately cell death. The use of Quats is especially common in food processing plants as tools for combating bacterial growth and contamination in the end-product. While this is effective for facility sanitization, it can potentially lead to problems in wastewater systems as they depend upon their inherent microbial community to function properly.

Effects of Quats in Wastewater

When a toxic substance like a Quat enters a wastewater system, it can drastically alter the microbial community, having a potentially major negative impact on the entire system. The main job of bacteria in wastewater is to digest organic material and remove it from the water. If a large portion of the bacterial population is wiped out by Quats, it can dramatically slow treatment, leading to disfunction and costly recovery expenses.

Resolving Toxic Upsets

To help resolve toxic upsets, wastewater facilities can treat their systems through bioaugmentation with Bacillus. Some Bacillus strains can survive high levels of Quats as well as degrade some quats into less toxic compounds. Additionally, some Bacillus can produce an enzyme called amine oxalase that gives them the ability to cleave Quats into smaller compounds with a much lower level of toxicity. The whole microbial community is involved in getting the wastewater environment back to where it was prior to an upset and the presence of Bacillus can give the system the kickstart it needs.

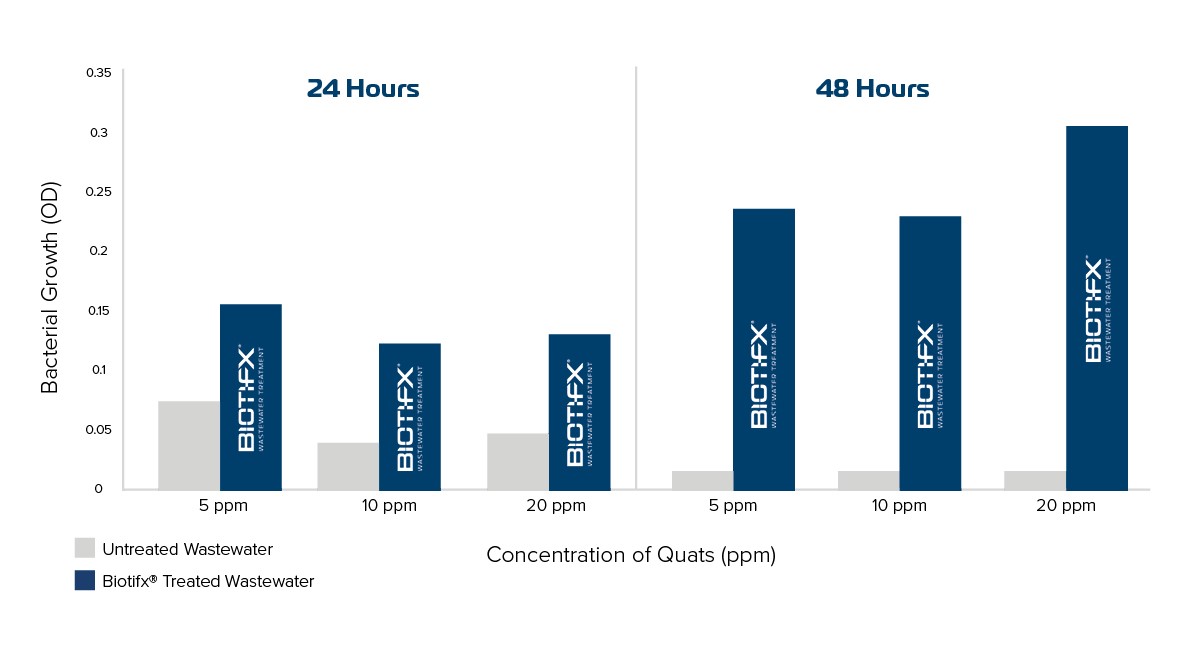

The below experiment (Figure 1) illustrates the recovery that’s possible with our Bacillus-based treatment Biotifx®. In the untreated wastewater sample containing Quats, the microbial community struggled to grow. The Biotifx treated community recovered quickly resulting in minimal performance interruption.

Figure 1: Bacterial growth in wastewater challenged with varying levels of Quats with and without Biotifx treatment.

For more information about our Biotifx products and distribution program, contact us and one of our wastewater experts will reach out to you.