If you’ve tried to buy any hand sanitizer lately, you’ll know how difficult it is to find, let alone at a normal price!

While the increased usage of sanitizers and disinfectants may be helping to protect us against the spread of germs, it has had a negative effect on the microflora balance in wastewater treatment lagoons. It’s also inspired some companies to market their bioaugmentation products as new solutions to this problem when the early users of bioaugmentation have been overcoming chemical upsets in wastewater and bioremediation for over 50 years.

Wastewater facilities face daily attacks on their microflora balance, not just from the increased usage of personal sanitizers, but also from routine activities like:

- Chemical sanitizers/disinfectants being washed down drains from processing facilities

- Changes in organic loading due to temporary shutdowns or product changeovers

- Acceptance of large loads of septic waste

- High levels of rainfall

Even lesser known is the fact that a facility recovering from an imbalance or “toxic upset” is more susceptible to additional upsets due to the delicate nature of the wastewater microflora.

The use of bioaugmentation products not only resolves toxic upsets, but also makes wastewater systems more resilient.

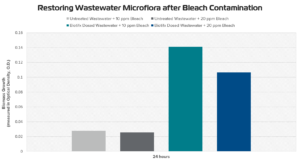

Over the next few weeks, we’ll share a series of articles that explain how Bacillus bioaugmentation products work along with data to illustrate results. Below is an example data set showing the fast pace at which our Biotifx® products respond to a toxic bleach upset (Figure 1).

While the Bacillus spores in our products are robust, not all strains work the same way, making it important that you consult with one of our experts to determine what solution is right for you.

If you would like to learn more about Biotifx® solutions, please Contact Us and one of our wastewater representatives will reach out to you.