Keep Up to Date with MDG

MDG News and Updates

MDG Employees Celebrate Cereal Drive Donations

As part of our Feed Clean Save vision, our team holds an annual cereal drive to benefit one of our favorite local charities: Hunger Task Force. This year, we went even bigger and upped our donation goal to 600 boxes. Sparked by some healthy competition, our team was able to exceed this goal and collected a total of 719 boxes of cereal for the Hunger Task Force Holiday Food Drive. To celebrate our success, we pied some brave MDG team members IN THE FACE! Can’t wait to up the ante next year! CLICK HERE to read more about this year’s event.

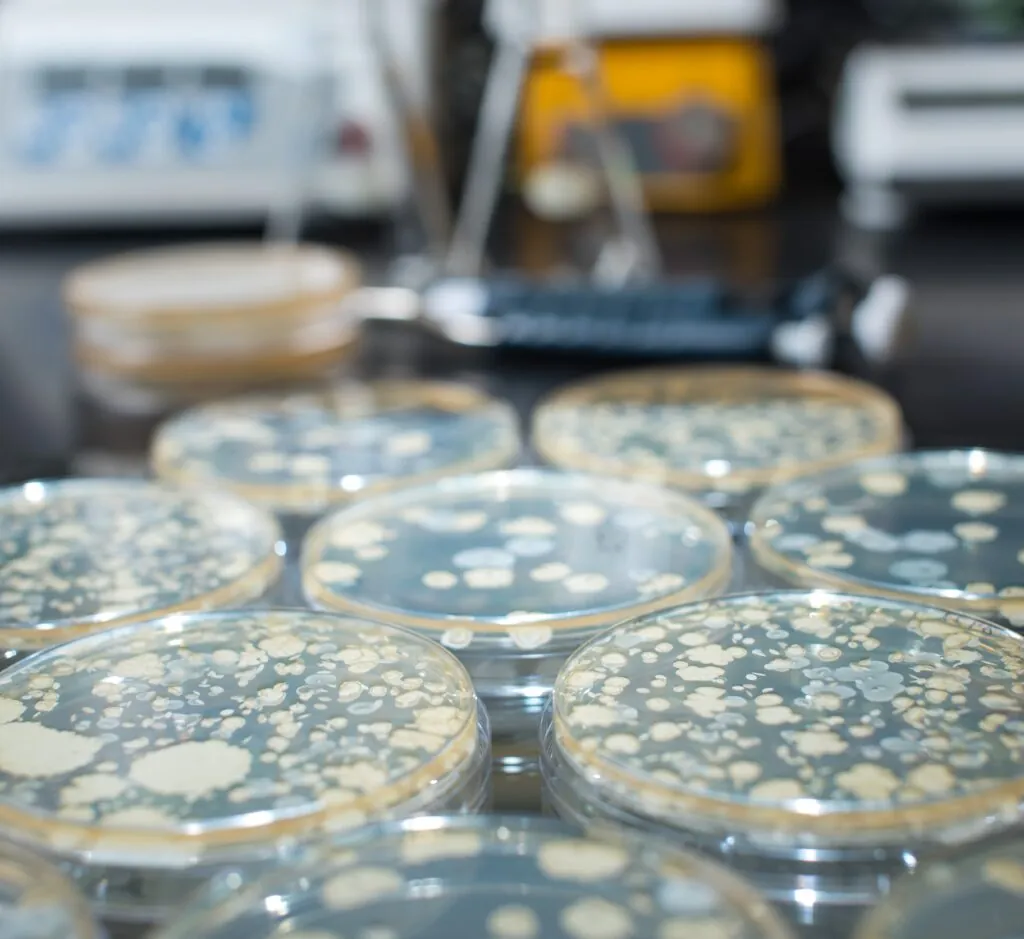

Bacillus Adaptation for the Utilization of Common I&I Odor Compounds

Bacillus are capable of using many types of organic material as a source of energy, and they are very good at adapting their metabolic processes to use whatever energy source is nearby. When sufficient nutrients are available, Bacillus will continually multiply. This is known as exponential growth. Figure 1. Growth of Bacillus when one energy source is available They will continue to grow until their preferred food source is exhausted. Then they will change their metabolic machinery and start using a different food source. During this metabolic shift, there will be a brief pause in growth while the Bacillus make the necessary changes; such as producing different enzymes. After this pause, exponential growth will resume. This process will repeat until all available nutrients have been exhausted. This characteristic of Bacillus makes it a sought-after ingredient in Industrial and Institutional products as Bacillus will continue to work until it has adapted to and utilized all available wastes. Figure 2. Growth of Bacillus when multiple volatile fatty acids are available Bacillus’ ability to grow exponentially in the presence of a food source was demonstrated in the following in-house study. This study measured SporActiv® Bacillus utilization of odor causing volatile fatty acids (VFAs). When one food source was available, Bacillus grew exponentially until that food source was depleted (Figure […]

Reduction of Ammonia by SporActiv™ Bacillus

When organic waste breaks down, it can generate ammonia, which is a toxic substance that produces a foul, sharp odor. In the Industrial and Institutional (I&I) market, your customers walk past ammonia-causing matter daily, such as food, animal and human waste. These same wastes contain materials that are rich in nitrogen. As the waste decomposes, the nitrogen is converted to ammonia, causing an unpleasant odor. But, without nitrogen, there’s no ammonia… and that’s where Bacillus come into play. All living organisms need a source of nitrogen to support life, including Bacillus. Bacillus strains can utilize the nitrogen in ammonia for bacterial growth. In order to get the nitrogen, Bacillus digest the available ammonia, removing it from the environment and preventing odor. RESULTS In the case of our SporActiv™ products, we specifically selected strains of Bacillus that have high ammonia utilizing capabilities. The more ammonia that is utilized by the Bacillus means less complaints and foul smells. At MDG, a study was conducted to measure the growth of SporActiv™ Foundation in the presence of ammonia. When ammonia was present, there was more bacterial growth, indicating the Bacillus were able to utilize the ammonia nitrogen to support growth (Figure 1). When choosing a Bacillus product, you should also keep in mind that not all Bacillus are able to utilize ammonia at […]

Case Studies: Seeing is Believing

We’ve heard it time and time again, “Does this stuff really work”? This sparked an idea. Why don’t we help our partners eliminate any doubt upfront by sharing in-field results? Better yet, let’s demonstrate how easy it can be for them to create their own. After all, seeing is believing! Through years of successful treatment and having now created 40+ case studies, our distribution partners have proven that these studies are the best tool for creating new believers in bioaugmentation. Because of this, we focus a big part of our training around taking key measurements in the field so that the creation of these case studies is possible. Our team of experts are hands-on in and the field with our partners, demonstrating when and how to properly gather data. As a result, partners can quickly and easily create case studies of their very own. Here are just some of the many benefits we’ve seen from building in a results-driven approach with our partners: Working hands-on in the field accelerates learning for our new distribution partners. Seeing is believing! Case studies validate that bioaugmentation products truly work. Having proof of this creates a strong marketing tool for future business. When our partners demonstrate measurable success […]

Microbial Discovery Group Kicks Off 2019 with a New Product Line for the Industrial and Institutional Cleaning Market

Microbial Discovery Group (MDG), a leading Bacillus fermentation company, announced their newest product line, SporActiv™, for the industrial and institutional cleaning market. MDG’s SporActiv liquid and powder product line contains safe ingredients that enhance a variety of residential and commercial cleaning needs. Applications include odor control, floor and tile cleaners, carpets, drains, portable restroom cleaning and more. As the market trends towards environmentally friendly and natural products, biological cleaning solutions will become increasingly prevalent. SporActiv is designed to stay ahead of this trend, bringing a full product line enhanced with both classroom and lab support services. MDG’s customer package includes training materials, lab data, research and more. “We wanted to create an offering that made it easy for our partners to do business while both meeting and exceeding cleaning manufacturer’s needs.” said Jenna Trusso, Marketing and Business Development. “In order to do that we knew we had to deliver a powerful cleaning ingredient while providing our partners with the speed and support they’ve been missing.” Built upon MDG’s extensive Bacillus library, the SporActiv Product Line includes a variety of different concentrations and bacterial counts. SporActiv also features a two-day shipping line, liquid and powder products, and water-soluble packages making it easy to incorporate the […]

Microbial Discovery Group Obtains HACCP Food Ingredient Certification

Microbial Discovery Group LLC (MDG) has expanded their HACCP scope which now includes food (human) ingredient. This has been part of their strategic plan and an important milestone in increasing their Bacillus fermentation capabilities. Having a Food Safety Plan and certification creates custom fermentation opportunities for MDG within the $44 Billion human probiotic market. This plan is a vital part of HACCP and the Food Safety Modernization Act and is a complementary piece to MDG’s recent fermentation facility expansion. “We’re excited to add food ingredient to our HACCP approved scope. This couldn’t have come at a better time, as we’re seeing the market space rapidly growing. What other market segments, such as plant and animal have seen over the past two decades is now being realized by the food industry for human consumption. If the trends hold true, we could see the human segment go from a 1% market penetration to well over 50% in a relatively short period of time. The other exciting thing is it offers our current and potential new customers a sense of comfort and peace knowing that the strains that they are purchasing are pure and are grown and monitored within a strict HACCP Program,” said MDG’s Business Development […]

Lift Stations 101: Work Smarter, Not Harder

Lift stations are commonly used as a part of operations across a variety of different industries. While they are extremely useful, they can be difficult to maintain when not cared for properly. At Microbial Discovery Group (MDG), we have spent countless hours in the field with our partners, reviewing their customer’s maintenance challenges, and looking for new ways to innovate. As a result, we were inspired to create a comprehensive approach to lift station treatment that can garner results quickly. LIFT STATION BASICS By design, lift stations are used to pump liquid, typically some form of wastewater or sewage, from a lower elevation to a higher elevation. This process begins when sewage is fed into the station and into an underground well. The well is furnished with several different float switches to detect the volume of sewage present. When the sewage level rises to a predetermined point, the pump begins to propel the sewage upward through a pipe system until it exits the station. From there, the sewage could be arriving to a wastewater treatment plant or to flow downward with gravity until it arrives at the next lift station. In some cases, the pump transports the sewage through a […]

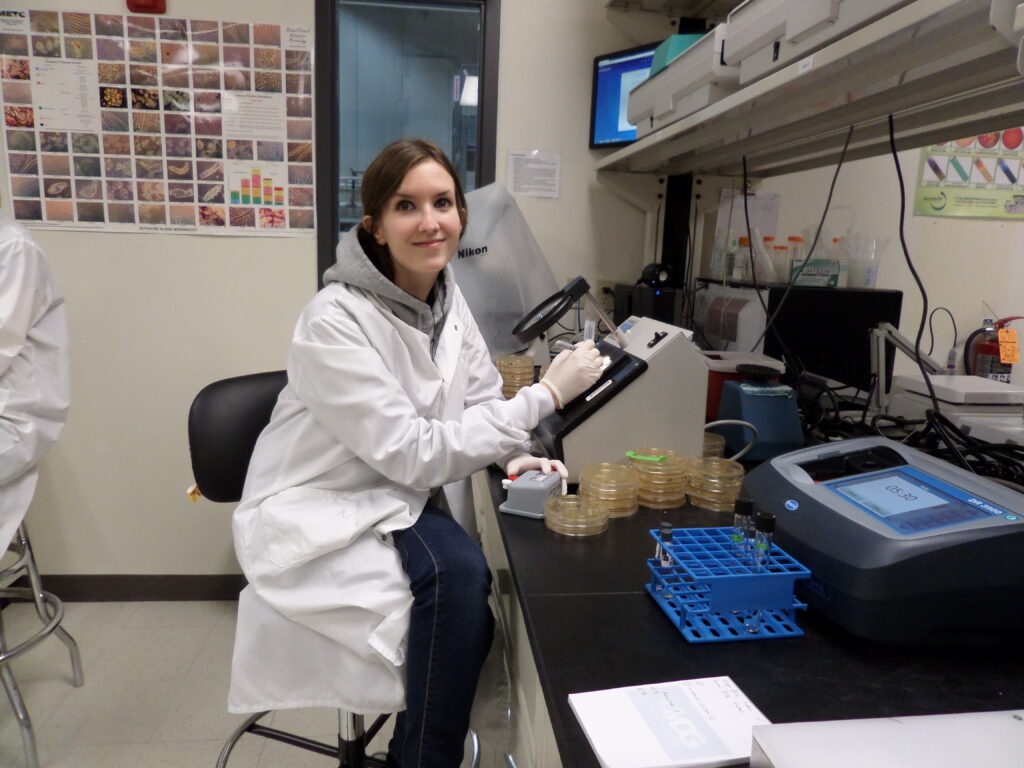

Under the Microscope, MDG’s Regulatory Microbiologist: Nicole DeGeorge

Our QA/QC team is constantly working hard to ensure both of our facilities are running in tip-top shape. Nicole DeGeorge is a key member of this team and most recently played an instrumental role in adding Food Ingredient to the scope of MDG’s HACCP Certification. 1. What drew you to Microbial Discovery Group? MDG caught my eye back in 2015. From working in third-party testing labs over a number of years, I already had a lot of regulatory and laboratory experience under my belt. MDG offered a rare opportunity to put some of the more specialized knowledge to use and to start growing my career in a unique way. I was also impressed by their commitment to helping communities near and far. Many companies are all talk when it comes to that sort of thing; on my first visit I was able to see how much they had accomplished through their Feed, Clean, Save (FCS) program. 2. What does your typical day look like? Over the years, this has been changing dramatically. I’m finding myself doing much more than just performing routine testing for our products. Recently, more and more of my time is spent programming/coding and developing technological solutions for handling […]

SporActiv® Water-Soluble Film: Makes Treatment Easy and Safe

As more and more people are working remotely, their sewage and septic systems are being put to the test. We’ve written recent articles highlighting the potential for backups and the various items that shouldn’t be making their ways into your septic tank. Good news, we’ve also touched on the strength of biological treatments. MDG manufactures pre-measured and easy-to-use septic tank pouches that work hard well after application to continue fighting potential back-ups. SporActiv® SepticPacs are pre-measured water-soluble packages created specifically for use in septic systems. To dose, it’s as simple as flushing the toilet. When first picking up these packs, you may be curious about the material. In your hands, it may feel similar to plastic, but fear not! The water-soluble packs are made of polyvinyl alcohol (PVA) film. When this film hits the water, it dissolves and the material becomes readily digestible by the SporActiv® microbes in the septic system. You may already be familiar with polyvinyl alcohol film as it has been used for many years to package detergents in “pods”. The same convenience of laundry and dishwasher pods is now available for septic treatment: no measuring, no spills, no fear of incorrect dosing. Every SporActiv® SepticPac delivers roughly 75 billion waste-degrading […]

Pandemic Recovery and Beyond

If you’ve tried to buy any hand sanitizer lately, you’ll know how difficult it is to find, let alone at a normal price! While the increased usage of sanitizers and disinfectants may be helping to protect us against the spread of germs, it has had a negative effect on the microflora balance in wastewater treatment lagoons. It’s also inspired some companies to market their bioaugmentation products as new solutions to this problem when the early users of bioaugmentation have been overcoming chemical upsets in wastewater and bioremediation for over 50 years. Wastewater facilities face daily attacks on their microflora balance, not just from the increased usage of personal sanitizers, but also from routine activities like: Chemical sanitizers/disinfectants being washed down drains from processing facilities Changes in organic loading due to temporary shutdowns or product changeovers Acceptance of large loads of septic waste High levels of rainfall Even lesser known is the fact that a facility recovering from an imbalance or “toxic upset” is more susceptible to additional upsets due to the delicate nature of the wastewater microflora. The use of bioaugmentation products not only resolves toxic upsets, but also makes wastewater systems more resilient. Over the next few weeks, we’ll […]