Keep Up to Date with MDG

MDG News and Updates

A New Kind of Rain is Coming for Wastewater Treatment Plants

We have heard from wastewater facilities that a lot of rainfall in a short amount of time can really throw off their ability to effectively treat wastewater. There is just not enough capacity and too little time to adjust. Unfortunately, we predict that a new kind of rain is coming. With recent concerns and actions around COVID-19, we’re seeing: 3.33 times the amount of water-related to handwashing Extra flushing to get non-toilet paper items to go down the toilet The first one might be a little easier to estimate. The CDC recommends washing your hands for 20 seconds, or the equivalent to singing happy birthday twice. But therein lies the problem wastewater treatment plants could be facing. In normal circumstances, the average person washes their hands for 6 seconds. So, with the increase to 20 seconds, we’re estimating 3.33X more water usage for handwashing. A normal faucet will use between 0.5 to 2.5 gallons per minute (GPM). If we take the average of that range, 1.5 GPM, and multiple it by the increased time spent washing, 14 seconds, you get 0.35 gallons of extra water used per person each day. But we’re not done yet! We also need to consider the uptick in how […]

Cleaning and Disinfecting: Different and Important

This message is for all of you cleaning at home and all the industrial and institutional (Jan-San) professionals; those of you who are cleaning our critical infrastructure facilities during this unique time. Thank you for your efforts and service. As a microbiologist who formerly worked for a chemical company who sold chlorine and bromine oxidizer products (similar to bleach), I suggest everyone take note of the CDC Recommendations to Clean AND Disinfect. These two common terms are both very different and important. According to the CDC, “cleaning refers to the removal of germs, dirt, and impurities from surfaces. Cleaning does not kill germs, but by removing them, it lowers their numbers and the risk of spreading infection. Disinfecting refers to using chemicals to kill germs on surfaces. This process does not necessarily clean dirty surfaces or remove germs, but by killing germs on a surface after cleaning, it can further lower the risk of spreading infection.” It’s likely that most people at work and at home are disinfecting right now, judging by the empty bleach shelves and inability to find Clorox wipes anywhere. While disinfecting is important, we need to be sure we are also cleaning. Cleaning removes dirt, debris, impurities and lowers the number of […]

Biotifx® Liquid Max FRZ

New Liquid Product for Winter Treatment Microbial Discovery Group (MDG) is excited to announce the launch of a new product for the Wastewater market. MDG formulated a new liquid cold water strain collection system treatment product, called Biotifx® Liquid Max FRZ. It allows you to outsmart the blizzards, sleet, and snow with Bacillus that remain active at low temperatures using scientifically selected strains. Keeping an automated dose of the Biotifx® Liquid Max FRZ during the cold months helps digest organic sludge, FOG and reduces H2S and odors, delivering consistent doses, frequently, and at scheduled times. What is Biotifx® Liquid Max FRZ: In addition to our cold weather Biotifx® FRZ line, Liquid Max FRZ is formulated with the same cold temperature Bacillus strains. The liquid version will conveniently treat wastewater treatment plants, lagoons, aerated sludge digester, industrial and municipal grease interceptors. Additionally, Liquid Max FRZ treats collection systems such as lift stations, force mains, sewer and gravity lines, or anywhere automation is desired, ideal in water temperatures 50F˚ and below. How does Biotifx® Liquid Max FRZ work: For many microbes, for every 10C˚ reduction in water temperature, reaction rates are cut in half. At these temperatures, the wastewater’s existing microbes don’t multiply and grow much because […]

MDG’s Zymobac® Product Is Now OMRI Listed®

MDG is excited to announce the OMRI listing for ZymoBac® GRO M50B, our solution for the Plant Health market. You can view ZymoBac® GRO M50B’s certificate here! “MDG is excited to announce that OMRI has reviewed ZymoBac® GRO M50B and has determined that it is Allowed for use in compliance with the U.S. Department of Agriculture (USDA) National Organic Program (NOP)!” Shannon Losing., Regulatory and Quality Manager of Microbial Discovery Group. What is ZymoBac® GRO? Our ZymoBac® GRO line chosen for its wide arrary of enzyme production to improve plant health and increase yields, and this listing now means that ZymoBac® GRO M50B can be used as a part of the USDA National Organic Program. We are proud that our Bacillus can be a part of organic agriculture, giving farmers a plant health product alternative to traditional materials. The organization that gives these listings is OMRI, the Organic Materials Review Institute. OMRI is a non-profit organization that reviews and lists products that follow the USDA in the National Organic Program. OMRI lists agricultural input products such as nutrients, pesticides, crop treatment, and animal feed additives. What does this listing mean for ZymoBac® GRO M50B users? OMRI informs producers about products that can be used in organic farming operations, making it easy […]

Under the Microscope, MDG’s Director of I&I Sales: Justin Howlett

MDG’s Director of I&I Sales, Justin Howlett, is ready to tackle the Industrial & Institutional market. What drew you to Microbial Discovery Group (MDG)? In my numerous conversations with Mike King, MDG’s CEO, I enjoyed the vision of the company’s growth as well as the challenge that was ahead in playing a role in getting the company to where it is now and where it will be. I enjoyed the culture that was and is so very important to Mike upon founding the company as well as how much he strives to keep it alive and thriving currently and for the future to come. What does your typical day look like? No day is “typical” in my role! On any given day you will find me intrenched in one of the following activities: working on training materials, interviewing candidates to expand our team, performing customer and industry research to understand what our partners might want from us, and/or discussing what MDG products would be helpful to add-on to our partners’ inventory. What is something at work that you’re passionate about? I enjoy the coaching aspect of my position. I assist my team by streamlining obstacles in our sales process so […]

Two Big Reasons You Need Our Small Spray Dryer

Throughout a facility tour at MDG you’ll walk past different sizes of the same equipment, one example, specifically of interest to many plant companies, is the 6-foot pilot spray dryer that stares up at a 34-foot electric production spray dryer. Flexibility in spray drying equipment size offers two intentional benefits: affordable trials and high-yield spore production. What is Spray Drying? MDG’s Pilot Spray Dryer Spray drying is used in markets such as custom fermentation, plant health, animal agriculture, wastewater, I&I, aquaculture, human probiotics, landfill, and bioremediation. This process involves drying liquid droplets into a fine powder. A nozzle that turns a stream of liquid into a fine mist allows for droplets ranging in micron sizes to be achieved and produce fine particles as the water droplets dry. Fine particle sizes are required for applying product through in field spraying applications making it a popular drying method for agriculture products. Affordable Trials Field trials are a common step in bringing a new strain or product to market. Field trials require a small amount of high-quality product and bringing a product to market requires high amounts of high-quality product. While that may seem like stating the obvious, few manufacturers are set-up to execute on […]

Trends of Today: Janitorial and Sanitation Market

All markets experience industry trends, both perils and opportunities. The key to success within any market is not simply navigating trends but getting ahead of the impact. As a Bacillus manufacturer for multiple markets, we tend to see overlap, allowing us to predict and forecast changes. Today, in the Janitorial and Sanitation industry, many of our partners are discussing trends that are both specific to the industry, and trends impacting markets across the globe. Lead Times and Availability Supply chain disruptions are felt across nearly all industries. Delays in raw materials, backlogged freight, and the rising demand has resulted in price spikes and the urgent need for replacement options. Green Ingredients Clean ingredient incentive groups all over the world have taken a hard look at manufacturers of products used for industrial, institutional, janitorial, and commercial cleaning. Of particular interest is the environmental impact these products elicit. Labor Shortages The Bearu of Labor and Statistics US Bearu Labor report stated that in 2021, 47.8 million and in early 2022, 4.3 million Americans “quit” their jobs. This has been deemed as the “Great Resignation” and because of this, companies are finding it hard to hire talent with the skills needed. Sustainability Environmental, social and governance (ESG) factors are […]

The Underlying Cause of H2S and How to Reduce It

Elevated hydrogen sulfide (H2S) levels are a serious concern for wastewater operators and introduce a variety of treatment challenges. While many treatment options reduce the symptoms of H2S (odors, safety risks, and corrosion), they are reactive and neglect the underlying culprit: sulfur-reducing bacteria (SRB). A discussion of H2S generation will aid in exploring the pros and cons of common reactive H2S treatment methods and how bioaugmentation can be a proactive treatment method. The Escalating Phases of H2S At low concentrations, H2S exhibits a rotten egg odor. At high concentrations, H2S can cause corrosion or physical harm including loss of consciousness or death in extreme cases. Understanding how H2S is generated and changes through its breakdown cycle is crucial to making informed treatment decisions (Figure 1). Figure 1: Sulfate breakdown in a typical wastewater environment. The process starts with sulfate, which is often present in wastewater. Normal levels of sulfate are harmless and natural. Sludge and fats, oil, and grease (FOG) are another common component of wastewater. When combined, sludge and FOG can create a reaction which removes oxygen from wastewater and potentially creates an anaerobic environment SRB thrive in anaerobic environments with high levels of sulfate. The higher the concentration of SRB, the higher the potential for H2S production. Most H2S treatments occur at this point in the breakdown chain, either by enhancing the non-SRB microbial community by introducing additives, or by removing H2S. If H2S goes untreated, […]

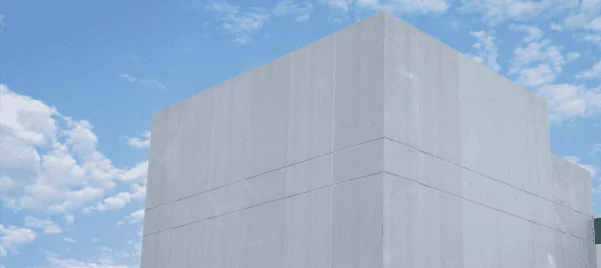

2021 Expansion Spotlight: New Spray Drying Structure

Microbial Discovery Group has broken ground on two new expansion projects in Oak Creek, WI, beginning the first of multiple 2021 capital expansion plans. Completion of the 2021 plan will result in a total investment of $2.7M into the Milwaukee-area. MDG’s business is built on supplying naturally-occurring, bacteria-based products to a multitude of different industries: bioremediation, wastewater, industrial and institutional, landfill, human health, aquaculture and more. Two projects are currently under construction and are scheduled to be completed by late summer, these include, an expansion of the powder blending room and the building of an external structure to house multiple spray dryers. MDG’s blending room will double in size, resulting in greater capacity and volume throughput in response to increased demand across all markets. This expansion is a foundational step, offering MDG the ability to add various blenders, powder milling equipment and additional equipment in future years. The external structure will house a new commercial spray dryer and pilot spray dryer, both currently being built off-site. MDG’s plant bioculture market will benefit from the smaller micron size of spray-dried culture, as they dissolve faster and can be incorporated into field applicator sprayers. Additionally, this development paves the way for additional […]

Alternatives to Ferric Chloride Offer Superior Economic and Treatment Improvements

Similar to many other chemicals, the price of Ferric Chloride has fluctuated over the years. While customers can typically handle slight changes, the industry has seen fluctuations in pricing, as large as, 4X the previous market average in recent years. For small to medium wastewater treatment plans, a price increase on a high-demand product, such as Ferric Chloride, encourages operators to search for alternative treatments. Does MDG offer a replacement to Ferric Chloride? Bioaugmentation is a direct replacement to Ferric Chloride that offers superior economic and treatment benefits in two main applications. Hydrogen Sulfide (H2S) Control: Ferric Chloride is often used as a sulfur binder in anaerobic digestors, aerobic sludge digesters, collections systems, force mains and lift stations as a sulfur binder. The Biotifx® line offers alternative products specifically focused on H2S abetment, backed by case studies and in-field success. Settling in Secondary Clarifiers: Ferric Chloride is used as a settling aid and percipient in primary and secondary clarification. Secondary clarification for biological waste activated systems that use Ferric Chloride can be replaced with bioaugmentation to improve the settling of that system. Is Bioaugmentation an easy switch from Ferric chloride? Bioaugmentation is a simple switch featuring a small footprint and minimal […]