Throughout the wastewater treatment process, certain components are left over that get separated from the treated water. This collection of leftovers is called sludge, which is then further treated in tanks. At Microbial Discovery Group (MDG), we have explored the process of treating sludge in sludge tanks and have designed our Biotifx® products and programs to assist with this treatment and ongoing system maintenance.

SLUDGE TANK BASICS

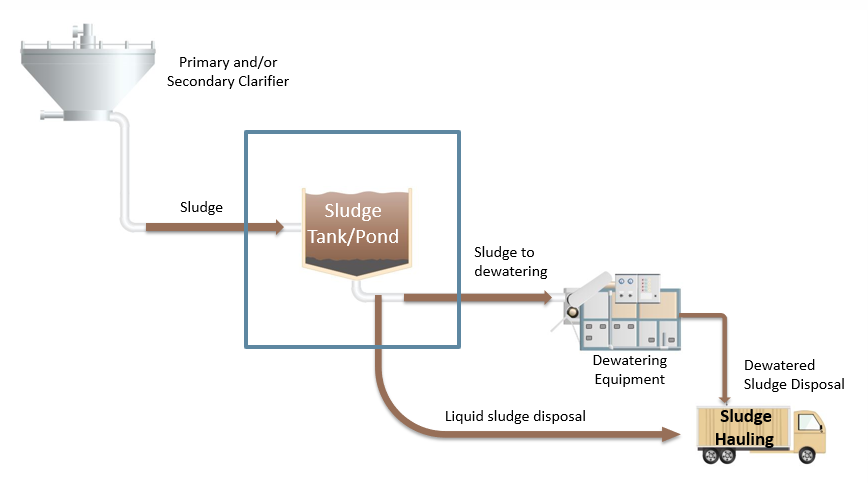

Sludge is a mixture of liquid and solid materials that have been removed from the treatment system. Essentially, it is the waste of the wastewater treatment process. Sludge is comprised of both organic and inorganic matter. After leaving the clarifier, sludge is transferred to designated tanks, which are accordingly called sludge tanks. These tanks can also be referred to as sludge thickeners, ponds, decanters, or digesters (not to be confused with aerobic digesters). After the sludge finally leaves the tank, it is dewatered through a sludge press and hauled away. Sludge tanks are utilized because they allow water treatment facilities to remove and store larger masses of liquid and solid waste, so they can continue treating wastewater in a more efficient manner.

The main objectives of sludge tanks are to:

- Increase digestion. By increasing the solids’ retention time, biology can continue to further digest the organic components of sludge.

- Thicken up the sludge by separating the liquid from the solid components. The tanks leverage gravity so that sludge settles at the bottom. Water can then be decanted, or removed, off the top.

- Act as a storage container before sending sludge for pressing and disposal.

THE PROBLEM: Sludge Tank Challenges

While sludge treatment is an essential part of wastewater treatment, the tanks come with some concerns surrounding their upkeep:

- Disposal Costs: When sludge is ready to be disposed of, it is carted off on trucks. Much like your mail, the sludge is measured and priced by weight. The heavier the sludge is, the higher the disposal costs. If you work to reduce the mass through digestion, disposal costs will decrease.

- Odor: This challenge comes as no surprise to anyone who has visited a wastewater treatment plant. After all, sludge isthe leftover waste of wastewater. Community complaints and regulatory fines can cause problems for cities and facility operators. While there are many causes of foul odor in sludge, one particularly unsavory offender is hydrogen sulfide (H2S) gas. This deadly gas is responsible for an unpleasant rotten egg smell and can cause health and safety risks for facility operators.

- Poor Dewatering and Inefficient Pressing: To avoid these two problems, operators employ a few different methods to remove water from the sludge composition and thereby reduce its weight. Because wet sludge is heavier than dry sludge, it is important to remove as much water as possible to keep costs down. To do this, however, facilities typically use polymers, which improve the settling and separation of water and sludge, but also drive costs up

- Limited Capacity: Sludge tanks can only hold so much sludge before they run out of room. The process is not always able to keep up with the amount of sludge coming in from the clarifier, especially when digesting and settling sludge. To combat this, facilities will often increase their capacity by adding new tanks, which can be a high-cost solution. However, when you’re able to improve digestion, you increase the amount of room available within and avoid the need to allocate money for additional tanks.

THE SOLUTION: Biotifx® Products + Platform

MDG’s research and development team works hard to create innovative products that will enhance efficiency within sludge tanks. The full line of our Biotifx® products is formulated with unique blends of Bacillus, enhanced with a proprietary blend of micronutrients and biostimulants to maximize microbial community performance. Biotifx® ST is the product specifically designed for sludge tank applications and focuses on increasing sludge digestion and improving dewatering. In addition to a great product, we’ve developed full education and training programs that take all the guesswork out of treating wastewater with bioaugmentation.

We want to ensure success every step of the way, so our Biotifx® platform was designed around creating a partnership between our technical experts and our distribution reps. We provide hands-on service and tools that accurately report results over time. Results with Biotifx® are real, and we enjoy working with our sales reps in the field to demonstrate impact through high ROI for their customers.

Sludge tanks are an important part of the wastewater treatment system, but they come with their challenges. MDG partners with distributors like you to help fix these issues so that sludge tanks can efficiently store and digest solid and liquid waste. This makes money for our partners and results in significant cost savings for their customers.

Are you interested in hearing about how we can increase your customers’ capacity without a single dollar spent on new infrastructure? Contact us to learn more about our Biotifx® Program.