When distributors participate in our Biotifx® program, they become armed with the knowledge and confidence they need to support their customers with superior microbial wastewater treatments – even during the winter months. The program includes onsite training, straightforward product application guides and tools, even an on-site technical service rep if/whenever needed. And cool products too.

Help Improve Cold Weather Performance

Colder temperatures during winter months can result in up to a 50% drop in microbial activity, drastically slowing wastewater treatment. Due to this, a few months prior to winter, our distributors switch their customers’ bacterial treatments to our unique Biotifx® FRZ strains, which help them maintain efficient system performance and counter seasonal upsets. It alleviates challenges associated with fats, oils, grease (FOG), sludge, odor and hydrogen sulfide and is ideal to use when water temperatures drop below 59°F / 15°C.

“Beyond sludge removal, you’ll lessen the typical spring turnover which comes with a large release of hydrogen sulfide when a lagoon flips. This saves on fines and additional maintenance.” – MDG Technical Service

Applications & Industries

Biotifx® FRZ can be used in a variety of applications including and not limited to:

- Lagoons

- Sludge Digesters

- Collection Systems

- Grease Interceptors

Common industries:

- Dairy

- Meat Processing

- Refinery and Petrochemical

- Fruit and Vegetable Processing

- Pulp and Paper

Lab Data

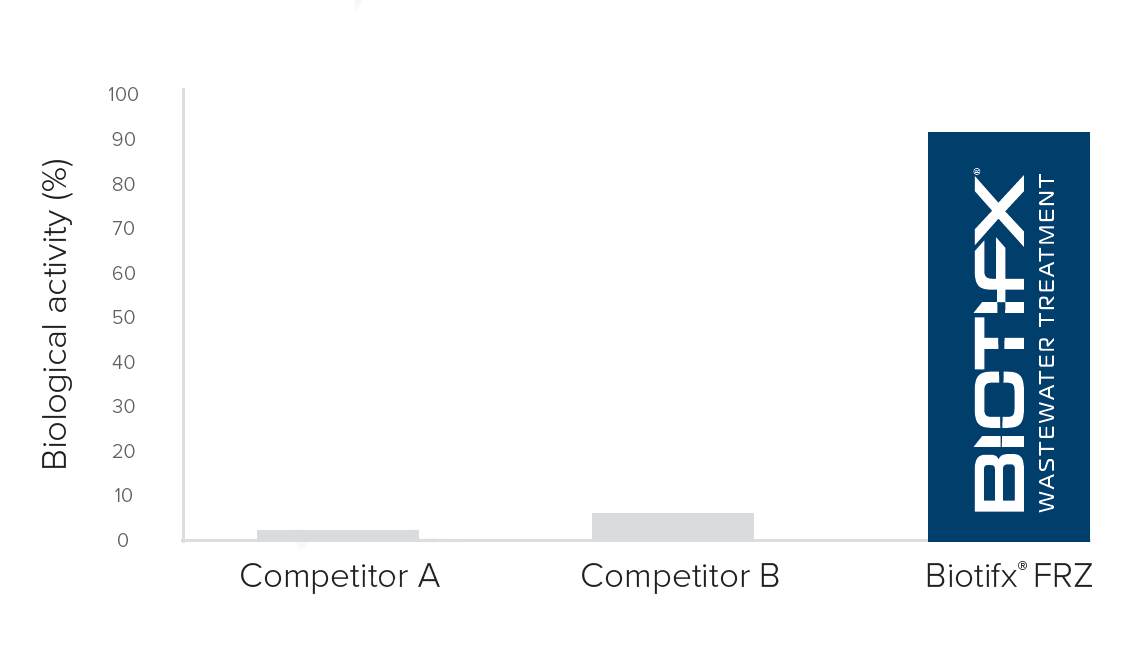

We put our proprietary FRZ strain to the test vs. competing cold temperature biological products. Biotifx® FRZ performance stayed consistently high across low and warmer temperatures. Biotifx® FRZ maintained 92% of its biological activity during a drop in temperature from 25˚C (77˚F) to 4˚C (39˚F) (Figure 1). In comparison, the two competitor products we tested showed only 1% and 5% of their biological activity during the same decrease in temperature.

Figure 1: Comparing biological activity at 4˚C (39˚F).

Figure 1: Comparing biological activity at 4˚C (39˚F).

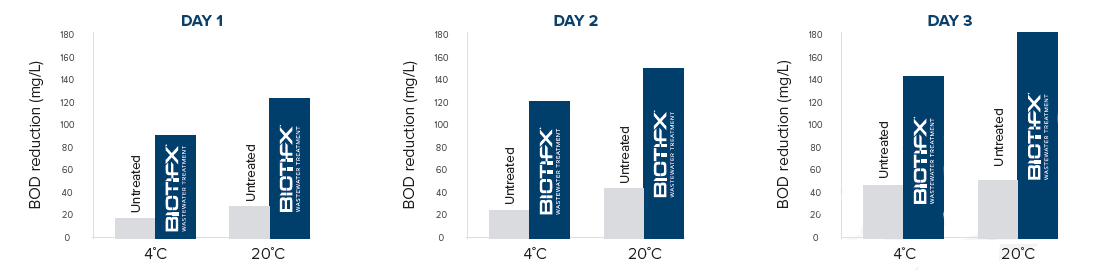

We also tested the effectiveness of Biotifx® FRZ in a dairy wastewater sample at 4˚C (39˚F) and 20˚C (68˚F). When the wastewater was untreated, the colder temperature severely limited reduction of BOD. Biotifx® FRZ improved BOD reduction during warm weather and continued efficacy while at at 4˚C (39˚F) (Figure 2). This allows for effective wastewater treatment throughout the winter and into spring.

Figure 2: Untreated vs Biotifx® FRZ BOD reduction in dairy wastewater

Figure 2: Untreated vs Biotifx® FRZ BOD reduction in dairy wastewater

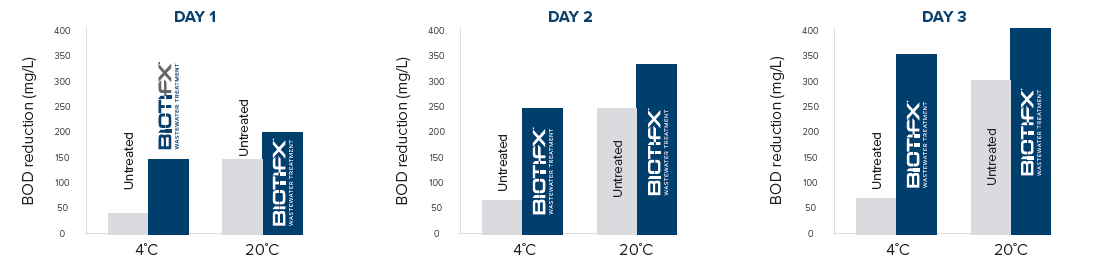

Lastly, we tested the application of Biotifx® FRZ in an industrial pulp and paper setting. Results were similar to our dairy wastewater test, but even more pronounced. Biotifx® FRZ greatly improved BOD reduction both during warm weather and cold weather compared to the untreated sample (Figure 3).

Figure 3: Untreated vs Biotifx® FRZ BOD reduction in industrial pulp and paper

To learn more about Biotifx® FRZ and how you can roll out our Biotifx® program with new microbial products for your customers, contact us and one of our wastewater representatives will reach out to you.